|

Workers from the LWF factory in College Point, Queens, New York City,

demonstrate the strength of the laminated wood fuselage of the Model V.

One of the earliest examples of the molded wood fuselage was produced by the LWF

Engineering Company in College Point, Queens, New York City. The LWF

company was formed in 1915 by Edward Lowe, Jr., Charles

Willard, and Robert Fowler, with each member contributing the

initial of his surname to form the company name. The chief asset of the

company was the laminated wood fuselage developed by Charles Willard.

After the pioneering founders were forced out the company by large

financial interests, the legend was promoted that LWF stood for

Laminated Wood Fuselage.

The only surviving example of the LWF Model V is in the National Technical

Museum in Prague, Czech Republic. The Model V was used by the early

Czechoslovakian Air Force in 1919.

|

|

The Loughead Aircraft Manufacturing Company's bid for "a poor man's

airplane" was the Loughead S-1, designed by Jack Northrop. The fuselage

was molded plywood.

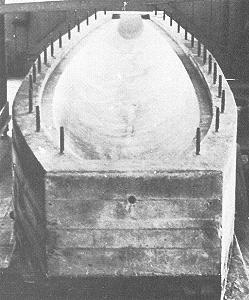

Another application of molded plywood construction was used by Jack Northrop

in the construction of the Loughhead S-1 using a 21-foot-long

concrete mold. In this mold were placed three layers

of spruce plywood strips, alternately laid, and well saturated with casein

glue. Once the strips were in position, the mold was covered with a rubber

bladder, and then a cover was bolted to the bottom mold. The rubber bladder inside

was inflated and pressure was maintained for twenty-four hours. The half

shells produced could be joined, making clean, smooth, bullet like

fuselages.

The S-1 was a distinct departure from pioneer and wartime aircraft.

Northrop's experiments resulted in a unique cigar-shaped, streamlined

fuselage that was of monocoque (French for "single shell") construction,

in which strength comes from the outside skin rather than internal bracing.

Northrop, Stadlman, and the Lougheads devised and patented a process to

make molded plywood monocoque fuselage shells

(US Patent #1,425,113, August 8, 1922).

Concrete mold in which monocoque wooden shell of the S-1 Loughead sport biplane of 1919 was formed.

|