| BMW 003 Turbojet |

| ||

|---|---|---|---|

| |

| ||

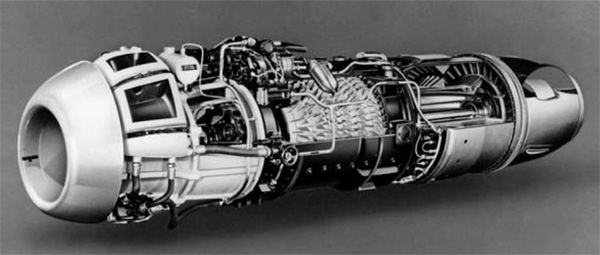

The BMW 003 axial-flow turbojet. |

|||

|

| |||

|

The BMW 003 was the world’s second successful axial-flow turbojet engine and powered the

Heinkel He 162 Salamander and four engine versions of the Arado Ar 234 Blitz. Although work had begun before its contemporary, the Jumo 004, the 003 went into production later due to developmental problems. The BMW 003 and Jumo 004 were the only axial-flow turbojets to go into production during World War II.

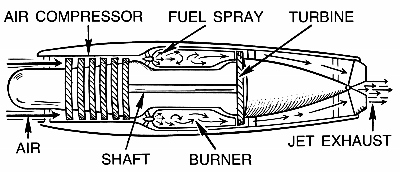

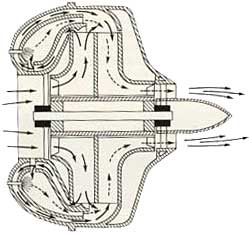

In 1938, the engine was developed through the Bramo P3302 Project, 109-002, at its headquarters in Berlin. Simultaneously, BMW was in the process of developing its own turbojet, the 109-003. Engine designations were assigned by the German Aviation Ministry (Reichsluftfahrtministerium or RLM). Bramo had been making the most progress and the company was acquired by BMW. The two projects were combined into the 109-003, with Hermann Östrich of BMW as head of the development team. In mid-1940, the first prototype was tested on a Messerschmitt Bf 110, but early results were disappointing. After the demonstration of the HeS 3 centrifugal jet (The HS-3 powered the Heinkel 178) designed by Hans von Ohain in 1937 proved that turbojets would actually work, the RLM approached Junkers Motoren (Jumo), Daimler-Benz, Bramo and BMW to develop their own turbojet designs. BMW and Junkers opted for a design that was revolutionary compared to previous centrifugal-flow turbojet designs by Hans von Ohain and Frank Whittle. Both BMW and Junkers opted to create an axial-flow turbojet which had a smaller cross-section. Early centrifugal turbojets use reverse-flow air through the combustion section, whereas an axial-flow turbojet allows air to flow straight through the engine, thereby creating less resistance. The smaller cross-section and more efficient air flow allowed an aircraft to travel at a greater speed. | |||

|

|

| Axial-flow turbojet with straight airflow. |

Centrifugal-flow turbojet with reverse airflow. |

| Development progressed slowly as the compressor and turbines of jet engines are very complicated with delicate components operating under high physical forces. Metal temperatures within an engine can reach as high as 1,800° F (980° C) and there was a shortage of needed metals such as nickel, cobalt and molybdenum. Today, titanium is used for compressor blades and high percentages of cobalt, nickel and chromium alloys for exhaust turbines, to withstand the extreme temperatures and stresses produced by jet engines.1 Although the metallurgy was understood at the time, the alloys just weren't available in sufficient quantities during early jet engine development. These alloys were scarce and simple metals were substituted in series production engines. The combustion chambers were made from mild sheet steel with an aluminum coating2 and since the heat resistance of these alloys was below what was required, the average life span of production engines was 25 hours. Overhauls were required after 10 hours.4 If the alloys had been available as required, this would have extended engine life to 150 hours.4 |

|

Ten prototypes were built between 1939 and 1941. Initial test results in 1942 were disappointing and the compressor air volume was increased by 30%. It wasn't until 1944 that the required 800 kp was produced. Production finally began in 1944, but due to developmental problems, full production was not achieved until early 1944.

Two early BMW 003 engines were installed on the Messerschmitt Me 262 prototype on November 25, 1941. It was decided to keep the Junkers Jumo 210G engine on the nose for safety reasons and as it turned out, it was fortunate that they did. Just after takeoff, both turbojet engines failed and if not for the piston engine on the nose, the flight would have ended in disaster. The airplane just barely made it back to the airport.5

A Junkers Ju 88 was used as a testbed for the BMW 003 turbojet. The first successful test of the BMW 003 was in October 1943, when installed on a Ju 88. In 1944, the engine successfully powered an Arado Ar 234 and achieved a cruising altitude of 13 km. The 003 had a single-spool, seven-stage compressor with steel blades, an annular combustion chamber with sixteen fuel nozzles, and single stage turbine. The hollow turbine blades were constructed of two-millimeter steel sheeting and cooled by air bleed-air from the compressor.

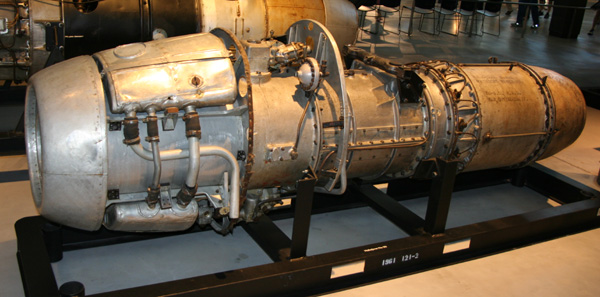

Ishikawajima Ne-20 turbojet. The Japanese produced a derivative, the Ishikawajima Ne-20, that was intended to power the Nakajima Kikka. After the war, BMW engineers who had emigrated to France, used their expertise to produce the SNECMA Atar. In Russia, the 003 formed the basis for the RD-20 which powered the Mig 9. Approximately 500 BMW 003 turbojets were produced before the end of the war but very few were actually installed on aircraft. By the end of the war, the BMW 003 produced 1,760 lbs. thrust. |

| Specifications: | BMW 003 Turbojet | Date: | 1944 | Type: | Turbojet |

|---|---|

| Compressor: | Single-spool 7-stage axial-flow | Combusters: | Annular combustion chamber | Turbine: | Single-stage |

| Length: | 143 in (3.63 m) |

| Diameter: | 27.2 in (.690 m) |

| Thrust: | 1,760 lbf (7.83 kN) |

| Dry Weight: | 1,375 lb (623 kg) |

Endnotes

|

1. Jack V. Casamassa and Ralph D. Bent. Jet Aircraft Power Systems. New York: McGraw-Hill Book Company, 1957. 292-299. 2. Dr. Daniel Uziel. Jet Engine Development in Germany. November 17, 2012. http://thefutureofthings.com/column/5887/jet-engine-development-in-germany.html 3. J.R. Smith, Antony L. Kay, E.J. Creek. German Aircraft of the Second World War. London: Putnam, 1985. 44. 4. Jack V. Casamassa and Ralph D. Bent. 5. 5. William Green. Famous Fighters of the Second World War. New York: Doubleday and Company, Inc., 1967. 120.

© Larry Dwyer. The Aviation History Online Museum. All rights reserved. Created September 3, 2013. Updated June 8, 2015. |