| The Hispano-Suiza Engine |

| ||

|---|---|---|---|

| |

| ||

|

|||

|

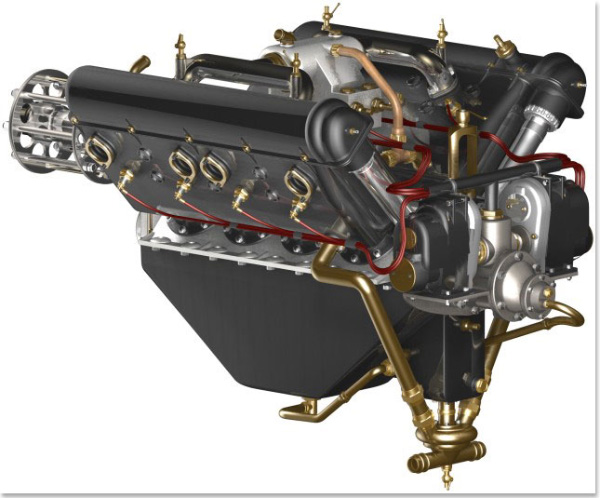

In 1915, Marc Birgikt, an automotive engine designer, created the Hispano-Suiza (Spanish-Swiss named for the financial backers), 150 hp, V-8 water-cooled aircraft engine. It was often referred to as the Hisso engine and the first plant was located in Barcelona, Spain. After outgrowing the capacity of the original plant, Hispano-Suiza engines were built under license in England, France and the United States. Hispano built engines were considered very good engines, but licensed built Hissos were known to be of dubious quality. | |||

| The Hisso differed form previous aero engines, by using a cast aluminum block with screwed-in steel sleeve inserts, instead of individual steel sleeves attached to the crankcase. This type of construction made for a stong, light weight engine, although it was extremely difficult to manufacture. Aluminum casting had not yet been fully perfected, and the precision of the long fine threaded sleeves were beyond the capabilities of most machinists at the time.1 Some of the original engine block castings were so poor that they were often discarded.2 |

|

The Wright-Martin built Hispano-Suiza engines incorporated some improvements made by Wright engineers in 1922, although they had to be derated to 150 hp to be of any use. Whereas, the French production models produced 180 hp from the start.3 The Wright built engines were of too little power for combat use and some went into Curtiss JN-4Ds. The French and British engines were also of too poor a quality to be used in wartime.

Wright had many problems in the beginning of production, but they claimed to have produced an aircraft engine that operated for longer periods at higher mean effective pressures than any other type of internal combustion engine at the time. Several types weighing less than 2-1/2 pounds per horsepower were tested for periods of 200 to 300 hours and required little attention. The Wright E4, with the same crankcase assembly, the cylinders only being changed, ran for 572 hours without attention of any kind. Compared with the original Model A, built 10 years before, the new engine with approximately the same weight and same displacement, developed one third more power, operated at 24 per cent more speed and had 3,000 per cent greater durability.

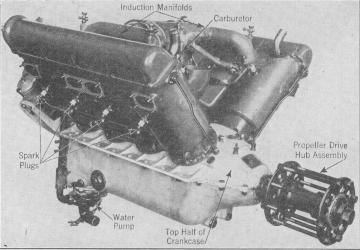

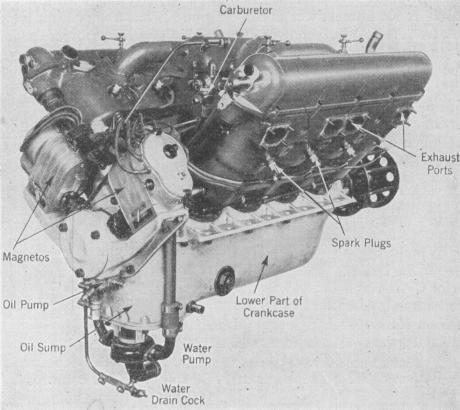

Fig 2. Wright 200 Horsepower Aviation Engine, Model E-4 has Eight Water-cooled Cylinders in Two Blocks of Four. During WW I, exhaust valves, connecting rod end bearings, and spark plugs gave the most trouble as the exhaust valves were too thin and prone to warping. Wright modified the cylinder, as shown at Fig. 3, and the use of tulip head silchrome steel valves greatly reduced valve troubles. In this respect the Wright-Hisso was somewhat better than the original. Refinement of details of the 1,947 cubic inches 60 degree V-type 12-cylinder Wright T-3 engine enabled it to be used satisfactorily at speeds greater than 2,200 rpm, and to develop 750 horsepower with approximately 140 pounds mean-effective pressure at 20 per cent less weight per horsepower than that of the original engine.

Fig 3. Wright "Tempest" E-4 water-cooled engine viewed from the rear showing magneto mounting and water pump location. After the Wright E2 engine, shown at Fig. 1 went out of production, it remained a popular type for some years. This engine had practically all of the characteristics of the Hispano-Suiza as previously described. The improved and refined Wright E4 shown at Figs. 2, 3 and 4 is the type that had been operated for 310 hours, before a new cylinder assembly was required, or long enough to have driven an airplane 31,000 miles without overhauling. After a new set of cylinders had been fitted, the other parts were run an additional amount so that the equivalent of 57,200 miles operation was obtained with only minor external adjustments. (This statment might be exagerated, since a continuous running engine wouldn't be under the same strain as one used for landing and takeoffs.) The old Model A engines developed a maximum of 175 horsepower at 1,800 rpm4, whereas the latest models of the same type developed a maximum of 285 horsepower at 2,300 rpm. The bore of the E4 cylinders was 4.710 inches, the stroke was 5.110 inches and the total displacement was 718 cubic inches. Hissos went out of production when the this amount of horsepower was suplanted by radial air-cooled engines.

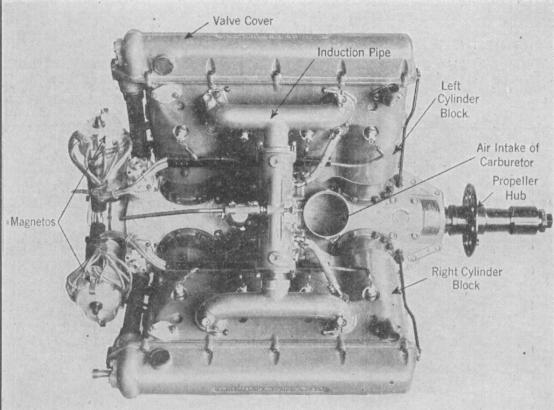

Fig 4. Top view of the Wright "Tempest" E-4 water-cooled engine showing carburetor and induction manifolding. |

| Endnotes |

|---|

|

1. Herschel Smith. The History of Aircraft Piston Engines. Manhattan, Kansas: Sunflower University Press, 1986. 67. 2. Ed. Fay L. Faurote. Aircraft Year Book 1919. New York: Manufacturers Aircraft Association, Inc., 1919. 277. 3. Herschel Smith. 67. 4. This was the advertised hp rate. The original Wright built Hispano-Suiza engine was derated to 150 hp. |

©Larry Dwyer. The Aviation History On-Line Museum. All rights reserved.

Created November 27, 2001. Updated October 12, 2013.