| Wright R-3350 |

| ||

|---|---|---|---|

| |

| ||

|

|||

|

| |||

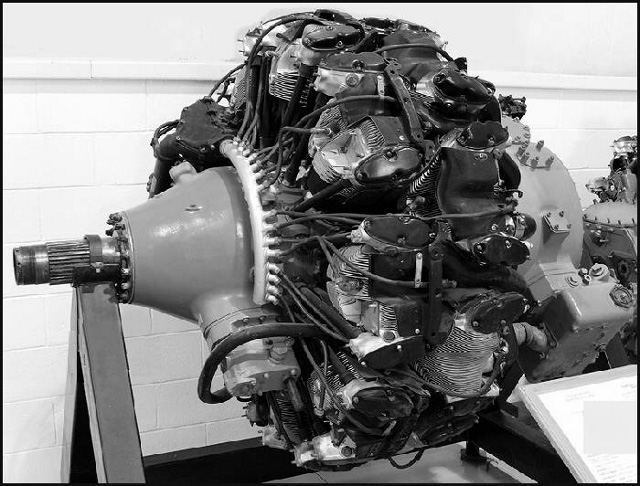

| The Wright R-3350 was a twin-row, 18-cylinder radial engine that was developed from the Wright R-1820 Cyclone and was one of the most powerful radial engines produced in the United States. Work on the engine began in January 1936 and the first R-3350 was run in May 1937. Development proceeded slowly due to the complex nature of the engine and concentrated effort on the Wright R-2600. It was similar in design to the company's R-2600 14-cylinder radial, sharing the same bore and stroke, but adding four more cylinders for additional displacement. Development accelerated after the USAAC issued its requirement for a long-range heavy bomber in 1940 resulting in the Boeing B-29 Superfortress. A serious effort was made then made to get the engine into production and the R-3350 finally made its first flight in 1941.1 | |||

| Wright Aeronautical built a new facility at Woodbridge, NJ for the R-3350 and shifted production at their Cincinnati plant exclusively to the Wright engine. Total output between these two plants approached 13,800. Chrysler's Dodge Chicago Division, supplied over 18,400 engines from their Chicago, IL location. |

|

To save weight, the engine crankcase was made of a magnesium alloy, however, magnesium is flammable metal and can produce a fire hot enough to burn through the aircraft structure. This happened on the second

Boeing B-29

prototype after an engine caught fire and burned the wing spar causing a catastrophic wing failure. All eleven crew members were killed, including Boeing’s chief test pilot, Eddie Allen.2

Other problems were encountered during early use as the engine tended to overheat and was prone to swallowing valves. During operational use in the Pacific, the hot climate and heavy loads caused serious engine overheating and magneto run-up checks were delayed and performed during the takeoff run to prevent engine overheating.3 Pilots learned to use as much of the runway as possible and build up speed to help cool the engines before slowly climbing for altitude. |

||

|

||

|

Altogether, the R-3350 went through tens of thousands of design changes during its early development. Improvements were made to reduce overheating, including changing from a downdraft carbureted system to fuel injection which eliminated inconsistent fuel/air distribution. This and other modifications gradually improved reliability. As design problems were overcome, the R-3350 saw its time between overhauls increase from 100 to 400 hours by the end of the war.

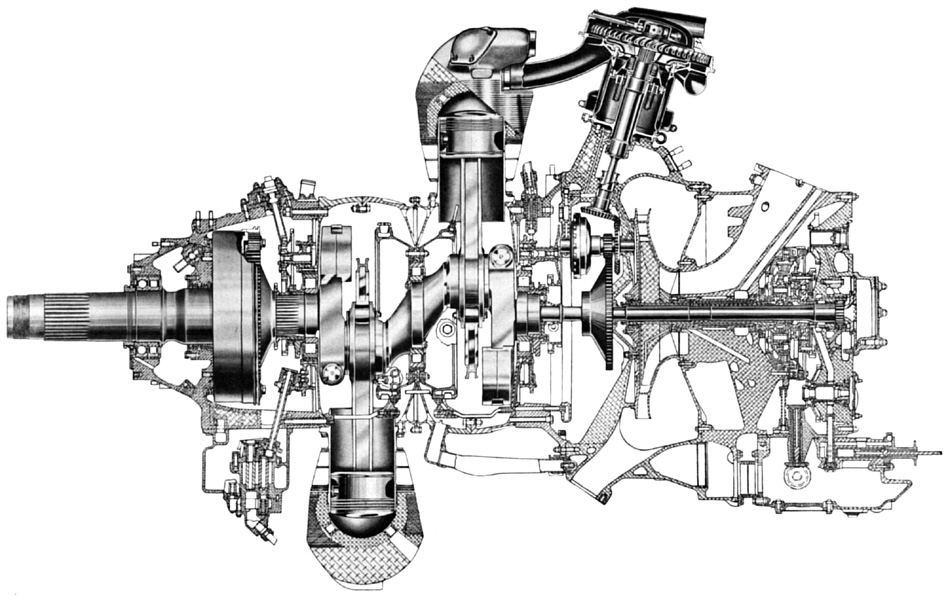

The civilian version of the R-3350 used a turbo-compound system that delivered better fuel efficiency and economy and the engine was favored for airline transports. It incorporated a Power Recovery Turbine (PRT) which boosted horse power up to 3,700 when using high octane 115/145 Avgas. (Avgas 115/145 was dyed purple and is produced only for racing today.) The PRT was an exhaust turbine drive mechanical device that was coupled directly to the engine crankshaft. Three PRTs were inserted into the exhaust piping of each group of six cylinders and were geared to the engine crankshaft by fluid couplings. PRTs recovered about 20 percent of the exhaust energy equaling about 550 horsepower at take-off power and 240 horsepower at cruise settings over a similar non-turbo-compounded R-3350. Operation of the PRTs is fully automatic the increased power was achieved with a weight penalty of about 500 pounds. Allison, Pratt & Whitney and Napier all carried out developmental work with the turbo-compounding concept, but Wright was the only aircraft engine manufacturer to put a turbo-compound engine into production. The first production turbo-compound R-3350s were delivered in March 1950. Initially, all Turbo Compound R-3350s were for the US military and commercial turbo-compounds were not produced until January 1952. An R-3350 was used on a Grumman F8F Bearcat Unlimited Class Racer and produced 4,000 hp at 3,200 rpm with 80 inches of manifold pressure and 4,500 hp with nitrous oxide injection at the Reno Air Races. Thousands of Wright R-3350s were built to power both military and commercial aircraft and were used in the Boeing B-29 Superfortress, Fairchild C-119 Boxcar, Lockheed C-121 Super Constellation, Douglas A-1 Skyraider, and commercial aircraft such as the Lockheed Constellation and Douglas DC-7. |

||

| Specifications: | |

|---|---|

| Wright R-3350 | Date: | 1937 |

| Cylinders: | 18 |

| Configuration: | Twin-row, air-cooled radial |

| Horsepower: | 2,200 hp (1,640 kW) |

| RPM: | 2,800 |

| Bore and Stroke: | 6.125 in. (156 mm) x 6.312 in. (160 mm) |

| Displacement: | 3,347 cu. in. (54.86 liters) |

| Weight: | 2,670 lbs. (1,212 kg) |

Endnotes:

|

1. Herschel Smith. A History of Aircraft Piston Engines. Manhattan, Kansas: Sunflower University Press, 1993. 118. 2. Peter M. Bowers. Boeing Aircraft Since 1916. New York: Funk & Wagnalls, 1968. 221. 3. Herschel Smith. 118. |

© Larry Dwyer. The Aviation History On-Line Museum. All rights reserved.

Created March 18, 2013. Updated October 12, 2013.