|

Boeing B-29 Superfortress |

|

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

The development of the B-29 can be traced back to the XB-15 through the B-17 to meet the USAAC requirement to carry 2,000 lbs. of bombs to the half-way point of 5,333 miles at 400 mph. | |

|

Monday morning, 8:30 a.m., 5 February 1940. It was raining and foggy (as usual). Phil Johnson (president of Boeing Aircraft Co.) grabbed a cup of hot coffee and sat down at his desk to go through the morning mail. He normally scanned all the envelopes before he read the letter, but this one caught his eye; "War Department, U.S. Army Air Corps, Wright Field, Ohio". Inside he found a thick document with a cover page, which began "U.S. Army, Airplane, Bombardment, Specification For". It was dated 29 January 1940. Thus began the long, sometimes tragic journey which would culminate in the Boeing B-29 Superfortress, unquestionably the most formidable bombing aircraft of the Second World War.

It was originally designated Boeing Model 334 in March 1938 but, after taking a few suggestions from the British (who were then using a small number of B-17Cs as Fortress Is for the RAF), Boeing began adding self-sealing fuel tanks, more armor, and state-of-the-art defensive armament amongst other refinements. When they were through, they sent the new specification to the Army Air Corps and redesignated it Boeing Model 345.1 The specifications were approved in June and by the end of 1940, Boeing had completed a mock-up. After an inspection and approval by the USAAC, two prototype "XB-29-BO" aircraft and a static test airframe were ordered and the Boeing-Seattle plant shifted into high gear. (The contract was amended for a third prototype on 14 December 1940.) Within five months, and before a single piece of the XB-29 had been manufactured, the Army ordered 250 more B-29 aircraft. Before the first B-29 ever flew, 1,650 were on order by the USAAF (In June 1941, the "US Army Air Corps" changed to the "US Army Air Forces"). Fourteen of the first batch were designated "YB29-BW" (These last two letters in the designation were for the company name and location of the manufacturing plant. "-BW" signified "Boeing-Wichita". "-BO" was used for "Boeing-Seattle in order to avoid "-BS"). The YB-29s would be the "Service Test" aircraft.

Fowler flaps increased the B-29's wing area by 350 sq. ft. The first problem was finding a wing to lift the giant. The USAAC was very concerned about wing-loading.2 A search for an "off-the-shelf" wing yielded nothing suitable. Any given wing would have enough lift, only to have too much drag at cruising speed. Another would have low drag but wicked stall characteristics. Yet another would have low drag, good stall characteristics and not enough lift to get the 105,000 lb. monster off any runway of reasonable length. The Solution? Boeing designed its' own wing, designated the Boeing "117" wing. When the wing design was finished, it was 141 feet long and had an area of 1,736 square feet. It had a set of flaps, which would increase the wing area by 350 square feet, for better control at slower speeds. With the flaps retracted, the wing had very low drag, which permitted higher speeds. Boeing had to devise a way to manufacture two wing spars which were the longest and heaviest Duralumin extrusions ever made. During destruction testing of the Boeing 117 wing, it took 300,000 pounds of pressure to collapse the wing. | |

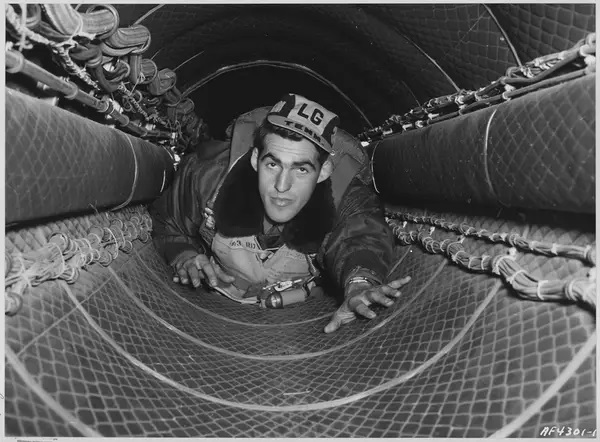

B-29 Pressurized communication tunnel. |

Early on, Boeing wrestled with the problem of crew comfort in the Superfortress. In smaller bombers, the problem was less severe because of their limited range. With the endurance of the Superfortress, the crew could be airborne for up to 18 hours at altitudes of 32,000 feet where the temperature could drop to 50° below zero. This meant the B-29 crew areas would have to be pressurized. But, if the plane was pressurized, how could you open 40 feet of the fuselage to outside air pressure at 32,000 feet in order to drop the bombs? The Solution; pressurize the areas fore and aft of the double bomb bay and connect the two sections with a large tube placed over the top of the bomb bays so airmen could get from one section of the ship to the other. |

|

Then there were problems with the huge, 16-½' Hamilton Standard propellers which caused "run-a-way" engines, problems with the four remote controlled gun "barbettes, problems with the "fire control blisters" where gunners were stationed to aim the barbettes; the blisters sometimes blew out when the craft was pressurized and flying at high altitude. (Gunners were advised to wear a safety line in order to avoid being blown overboard if a blister popped). There were problems with booster controls for the rudder and problems with the radar.

The first XB-29 was originally equipped with three-blade propellers. This aircraft was used for testing and lacked armament. | |

|

Finally on Monday, 21 September 1942, in front of almost all the Boeing employees who had contributed over 1,300,000 man hours to the Model 345 project, Number One XB-29 was rolled out on the runway at Boeing Field, Seattle. Engines were warmed, takeoff power was applied and Eddie Allen, Boeings Chief Test Pilot lifted the first Superfortress off the runway as smoothly as if he'd been doing it for years. The 52-½ ton craft rose steadily to 6,000 feet where Allen made the preliminary tests of the controls for pitch, yaw and roll. After a 1-½ hour flight, he brought the huge aircraft back to a smooth landing. The second prototype flew three months later.3 As a measure of the problems yet to be solved; in the 97 days following that first flight, Allen was able to accumulate only 27 hours flight time in No. 1. However, as a measure of the fundamental integrity of the aircraft itself, not a single basic alteration to the airframe was required throughout its' production history. |

Eddie Allen, Boeing's Chief Test Pilot. |

|

The Wright R-3350 Cyclone engine had persistent problems.

Cpl. John J. Green and Cpl. Robert L. Cover change a turbo-supercharger in Okinawa.

|

The most relentless problem was the 2,200 hp Wright R-3350 Duplex Cyclone engine. It had a persistent inclination to overheat, swallow valves and even catch fire in flight. In an effort to produce more horsepower from a lighter engine, the crankcase was made of magnesium, a very light, very strong metal. The problem was magnesium is also a flammable metal. When that was combined with the additional problem of a fuel induction system, which tended to catch fire and burn long enough to catch the magnesium afire, it became a very serious situation. "Band-Aid" treatments such as air baffles to direct more air to the rear row of cylinders and propeller cuffs to force more air through the engine helped, but it would be many moons before the problem was solved. Boeing lost its' Chief Test Pilot along with the cream of the B-29 flight test crew because of a fire which destroyed a wing spar. Shortly after noon on Thursday, 18 February 1943, Eddie Allen was flight testing the number two XB-29 when an engine fire developed. The port wing spar burned through and collapsed sending the huge bomber crashing into a meat packing plant a few miles south of Boeing Field. All eleven men aboard the plane and 18 in the plant were killed instantly. |

|

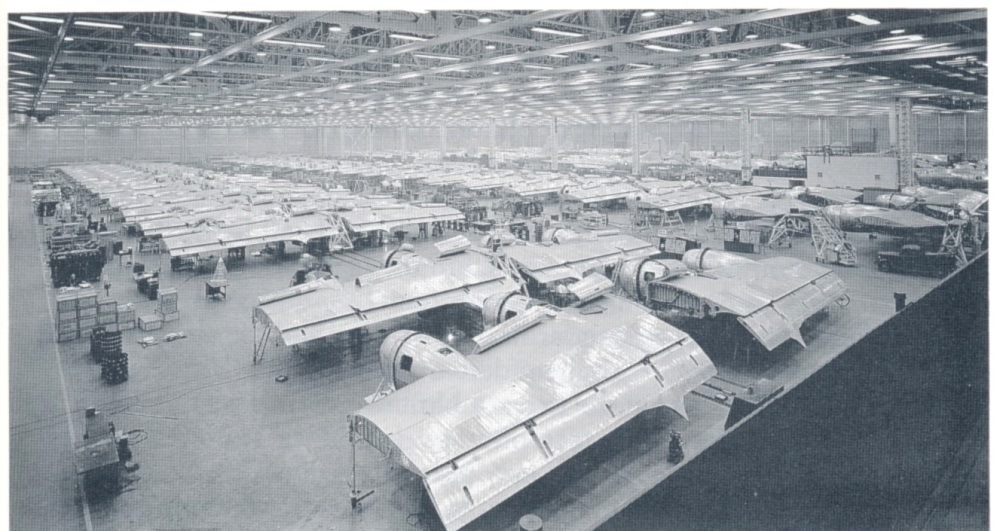

Eventually, Senator Harry S. Truman (who would later become President Truman) headed a committee looking into the problems of the Wright R-3350 engine. The committee found Wright Aeronautical at fault for letting quality go by the boards in favor of quantity. Equally at fault, according to the committee report, was the USAAF for putting too much pressure on Wright to speed up production of the R-3350. Though the problems weren't completely solved, by the end of 1943 they were under control to the extent Boeing-Renton and Bell-Marietta began turning out the first of nearly 2,000 B-29 Superfortresses contained in the initial orders for delivery to the USAAF. |

The Frye Packing Company in flames, the site of the XB-29 crash. |

|

The B-29 was armed with the General Electric auto-computing fire control system composed of eight remotely-controlled 0.50 caliber machine guns installed in four barbettes located on the top and bottom of the fuselage fore and aft. Later models added two more machine guns to the top forward barbette to assist in defending against frontal attacks. Control of the four barbettes could be transferred to a single gunner or shared between front, right, left and top gunners. The tail-gunner controlled two more .50s plus a 20 mm cannon. It was estimated the tail gunner accounted for 75% of all enemy planes destroyed by the Superfortress. One reason for this was the 20 mm cannon. Another was the slow closing rate of an enemy approaching from the rear which allowed more time for the tail gunner to sight on the intruder. Initially the B-29 had a maximum permissible weight of around 105,000 pounds which was quickly upgraded to 138,000 pounds. During the latter phases of the war with Japan, gross take-off weights of well over 140,000 pounds were fairly common for the Superfortress. A whopping 40% of the fuselage was dedicated to carrying bombs. The double bomb bay could carry 16,000 pounds to a target 2,050 miles away and return to base. It took 6,988 gallons of 100 octane aircraft fuel to fill the tanks. The maximum capacity was 9,548 gallons with ferry-tanks in the bomb bays, in which case the range was extended to 6,000 miles.

The B-29 internal double bomb bays would normally carry 16,000 lbs. and a maximum of 20,000 lbs. The Superfortress was furnished in two basic configurations. There was the "F13" photo version which was used to obtain target photos of Japan and in fact the entire western Pacific and eastern Asia area. And, there was the B-29, B-29A and B-29B, all of which appeared identical, though their "innards" were sometimes very different. As each Superfortress rolled down the assembly line, it was given the latest USAAF modifications which resulted in 3,974 B-29s each of which was just a bit different from the next.4 The Superfortress acquitted itself well in the Pacific war despite mechanical and electronic problems. At first, it wasn't unusual for a mission to lose more aircraft to mechanical problems than to the enemy. On 10 February 1945, eighty-four of 118 B-29s dispatched from the 73rd and 313th, attacked the Nakajima aircraft plant at Ota and 14 attacked other targets. Eleven of the twelve B-29s lost on the mission succumbed to operational accidents and mechanical failures. But, as the Crew Chiefs became more adept at field modification, the numbers slowly began to improve. The major factor in creating an efficient bombing machine out of the Superfortress was an Air Forces Major General named Curtis E. LeMay. Nicknamed "Iron Ass", LeMay was put in command of the Marianas based B-29s and was responsible for solving several of the Superfortress and operational problems in one stroke: He ordered the B-29 crews to remove the guns (the tail guns were replaced with broom sticks so the enemy fighter pilots, hopefully, wouldn't become aware of the missing guns). Also the gunners and all the ammunition were to be removed. And he ordered the missions flown at 8,000 to 12,000 feet. Bombing accuracy had been miserable because of the high winds at the 28,000 to 34,000 foot level where previous mission had been flown. Aborts were common because of engines which overheated in the process of climbing to which altitude. With the new procedures, fuel could be saved, without the weight of guns, ammunition and gunners, more bombs could be carried, engines would run cooler and bombing would be done from below the fierce winds raging over Japan.5

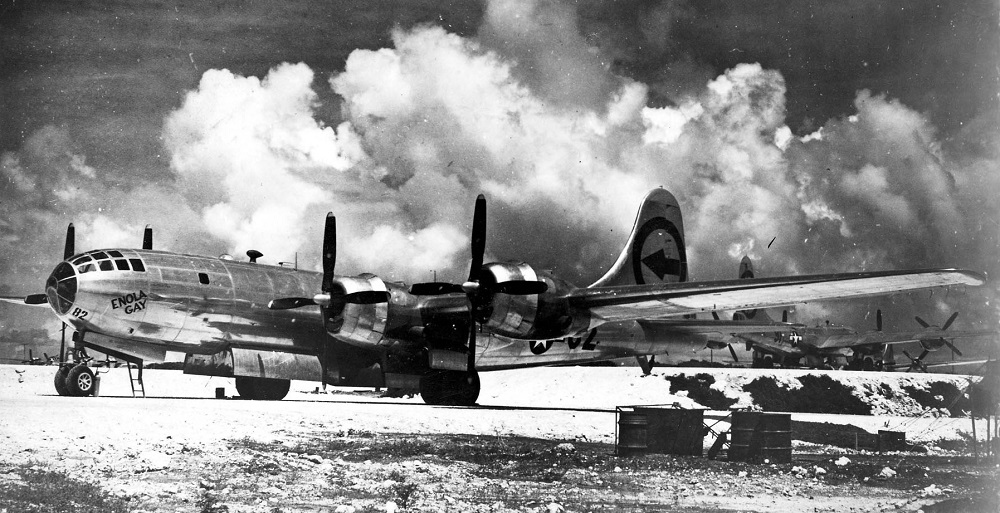

The Enola Gay was the world's first aircraft to drop an atomic bomb. The bomb was dropped from 31,600 feet on Hiroshima, Japan on 8 August 1945 at 8:15:17 a.m. LeMay faced a near-mutiny from his crews who were certain Japanese flak batteries would rip them to pieces at such a low altitude. And he knew his butt was on the line to his superiors if it turned into a massacre. But he stuck to his decision and it was a good one. Casualties went down, the number of targets destroyed rose dramatically and the number of aborts due to overheated engines dropped. The air war against the Japanese home islands entered a new and apocalyptic phase where city after city was nearly obliterated by firebombs. The city of Toyama was 99.5% destroyed in one raid by 173 B-29s on the night of 1 August 1945! At 2:45 am, Monday, 6 August 1945 an ordinary looking B-29-45-MO, serial number 44-86292 sat at the end of the runway at North Field, Tinian, an obscure little island in the Marianas Group of the western Pacific. The engines were run up one at a time, a spot light illuminating each to check for undue smoke or other disorder. The only thing peculiar about the ship at all was the name; no raucous female nude in a suggestive pose painted on the nose, just the rather unremarkable printing: "Enola Gay". Sitting in the left seat was Colonel Paul W. Tibbets, Jr., commander of the 509th Composite Group; in the right seat was Captain Robert Lewis. The Group had been at Tinian since June and curiosity amongst the other Groups was mounting. The 509th didn't seem to have a particular mission, just a few "training" flights to Truk and other low priority targets in Japan itself. They kept their distance from the other Groups, didn't mingle at all. In another few hours, the whole world would know of the mission of the 509th Composite Group and this particular aircraft, the Enola Gay. Lifting 75 tons off the runway, she was on her way to Japan. At 8:15:17 a.m. the Enola Gay was over Hiroshima, Japan at 31,600 feet when the world's first atomic bomb to be dropped from an aircraft, was toggled. Two minutes later it exploded over the city at an altitude of about 2,000 feet. The bomb wiped out a circle 4.5 miles in diameter in the middle of Hiroshima. On August 9, another atom bomb was dropped on Nagasaki. Six days later, the Japanese unconditionally surrendered. Thus the end of World War II was brought about in no small measure by the Boeing B-29 Superfortress.6

The Boeing B-29 Superfortress "Enola Gay" at the National Air and Space Museum. | |

| Specifications: |

|

|---|---|

| Boeing B-29A Superfortress |

|

| Dimensions: |

|

| Wing span: |

141 ft. 3 in (43.05 m) |

| Length: |

99 ft. 0 in (30.17 m) |

| Height: |

27 ft. 9 in (8.45 m) |

| Wing Area: |

1,739 sq ft (161.3 sq m) |

| Weights: | |

| Empty: |

69,610 lb (31,574 kg) |

| Maximum Take-Off WW2: |

105,000 lb (47,627 kg) |

| Maximum Take-Off Postwar: |

140,000 lb (63,502 kg) |

| Performance: | |

| Maximum Speed: |

399 mph (642 km/h) at 30,000 ft (9,144 m) |

| Cruise Speed: |

220 mph (354 km/h) at 50% power |

| Service Ceiling: |

31,850 ft (9,707 m) |

| Combat Ceiling: |

36,150 ft (11,018 m) |

| Normal Range: |

4,200 miles (6,759 km) (with 18,000 lbs. (8,164 kg) bombs) |

| Powerplant: | |

|

Four Wright R-3350-57 Duplex Cyclone twin-row radial

2,200 hp (1,640 kW) take-off, 2,500 hp (1,864 kW) WE, air-cooled | |

| Armament: | |

|

Eight or twelve 50-cal. machine-guns. One 20mm cannon.

Maximum bomb Load: 20,000 lbs. (9,0710 kg) |

Endnotes:

|

1. Chris Chant. From 1914 to the Present Day, The World's Great Bombers. Edison, New Jersey: Chartwell Books Inc., 2000. 136. 2. Peter M. Bowers. Boeing Aircraft Since 1916. Annapolis, Maryland: Naval Institute Press, 1989. 319. 3. F. G. Swanborough. United States Military Aircraft Since 1909. London: Putnam & Company Ltd., 1963. 85. 4. Peter M. Bowers. Boeing Aircraft Since 1916. New York: Funk & Wagnalls, 1968. 281. 5. Dr. Alfred Price. Instruments of Darkness. London: Greenhill Books, 2005. 245. 6. David Mondey. The Concise Guide to American Aircraft of World War II. New York: Smithmark Publishers, 1982. 32. |

Return To Aircraft Index.

© Earl Swinhart. The Aviation History Online Museum.

All rights reserved.

Created August 3, 2000. Updated January 30, 2023.