|

|

Hawker Typhoon and Tempest |

|

|

|

|

|

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|||

|

||

|

| ||

| It is an accepted maxim for successful aircraft development that future requirements should always be the principal concern of the chief designer and his project design team. The company which allows itself to become wholly preoccupied with the development of an established design may produce as a result an outstanding aeroplane, but the policy is a shortsighted one if no new prototype is following to consolidate this success. Thus, the fact that Sydney Camm, Hawker Aircraft's chief designer was at work on a new fighter as a potential replacement for the Hurricane as early as 1937, when the first production aircraft of that type had still to fly, reflected no lack of confidence in the Hurricane's potentialities, but the natural desire to ensure that its service successor would be a product of the same stable. |

| This massive new fighter, the heaviest and most powerful single-seat single-engined warplane envisaged at the time of its design, was to suffer a long gestatory period. It was to be pressed into operational service before it was fully developed and in consequence, acquire a worse reputation among its pilots than that of any fighter preceding it. It was fated to be rarely employed in the interceptor role for which it was originally conceived. Yet, despite its vicissitudes, it was to blossom into one of the most formidable weapons evolved during the Second World War. It was a close-support fighter that was to turn the scales in many land battles and upset many conceptions of land warfare. |

|

In January 1938, barely two months after the debut of the first production

Hurricane,

Hawker Aircraft received details of specification F.18/37,

calling for a large single-seat fighter offering a performance at least

20 per cent higher than that of the

Hurricane

and achieving this with the

aid of one of two 24-cylinder engines in the 2,000 hp class then under

development --the

Napier Sabre "H" type and the

Rolls-Royce Vulture "X"

type. Sydney Camm had commenced investigating the possibilities of just

such a fighter in March 1937, and had already roughed out a design built

around the

Napier Sabre

engine and housing twelve

0.303-in. Browning

guns with 400 rpg in its 40-foot wings. At the proposal of the Air

Ministry, Camm also prepared studies for an alternative version of his

fighter powered by the Rolls-Royce Vulture

engine, and increased the ammunition capacity of both machines to 500 rpg.

Further discussions over military loads and equipment followed and revised tenders were submitted throughout 1938. The Air Ministry at the beginning of 1938 sought both the Type " N " and the Type " R " as the alternative Sabre and Vulture powered fighters had become known. These tenders were formally accepted on April 22, 1938, and four months later on August 30, two prototypes of each fighter were ordered. Structurally both types were similar: the wings were all-metal, the front fuselage was of steel tubing, and the aft section consisted of a stressed-skin, flush-riveted monocoque—the first Hawker designs to employ this form of construction. Uniformity between the two fighters was in fact achieved to a remarkable degree, but the designs did differ in one important respect initially—the Vulture-powered fighter made use of a ventral radiator while the Sabre-driven machine had one of "chin" type.

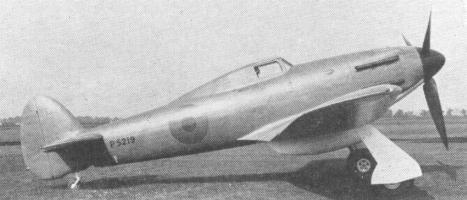

The first Tornado prototype (P5219) with ventral radiator. Construction of the two massive fighters proceeded in parallel and work progressed simultaneously on the preparation of production drawings. As a result of the slightly more advanced development status of the Vulture engine which had been designed along more conventional lines than the Sabre, the Type " R " was the first of the two fighters in the air flying in October 1939. Named appropriately enough Tornado, the initial flight trials of the prototype were promising and a production order for 1,000 Tornados was placed at the beginning of November. It was proposed that the new fighter should be built both by Hawker and by A.V. Roe at Woodford. However, the flight test program soon began to run into trouble. Compressibility effects, about which little was known at that time, began to manifest themselves and it was decided that the ventral radiator bath was unsuitable for the speeds approaching 400 mph that were being achieved for the first time. The radiator was therefore moved forward to the nose, a position already selected for that of the Type " N ", by now dubbed Typhoon. However, the first prototype Tornado (P5219) only flew long enough to indicate the beneficial results of the change before it was totally destroyed. Meanwhile, on December 30, 1939, the first Napier Sabre engine had been delivered to Hawker Aircraft and the first prototype Typhoon (P5212) emerged from the experimental shop to fly on February 24, 1940. It too became the subject of a quantity production order which it was planned, should become the responsibility of Gloster Aircraft, whose assembly lines were emptying of Gladiator biplanes and whose design office was already immersed in the development of the Gloster Meteor, the first British turbojet-driven aircraft. Although, like those of the Tornado, the first flights of the Typhoon prototype indicated a promising fighter. The machine proving relatively easy to fly at high speeds, although its low speed qualities left much to be desired, and it had a marked tendency to swing to starboard during take-off. The "X" form of the Tornado's Vulture engine had not permitted installation above the front spar as was the Typhoon's Sabre. In consequence, the overall length of the former was 32 ft. 6 in. as compared with the 31 ft. 10 in. of the latter. Owing to the size and weight of the Sabre and the need to preserve c.g. balance, the Typhoon's engine was fitted so close to the leading edge of the wing that severe vibration was experienced as the slipstream buffeted the thick wing roots. On an early test flight the stressed-skin covering began to tear away from its rivets and the Typhoon's pilot, Philip G. Lucas, only just succeeded in bringing the prototype in to a landing. Apart from structural teething troubles, the Sabre engine, although a compact and exquisite power plant, called for a considerable amount of development and it was perhaps fortunate for the future of the Typhoon that in May 1940, the grave war situation led to the cancellation of all priority for Typhoon and Tornado development in order to allow every effort to be put into the production of sorely needed Hurricanes, but design development was allowed to continue. However during 1940, three alternative engine installations were proposed for the Tornado—the Fairey Monarch, the Wright Duplex Cyclone , and the Bristol Centaurus—and experimental drawings for the Centaurus installation were completed. Development on the Typhoon included the design of a modified wing containing two Hispano 20 mm cannons in place of the six 0.303-in. Brownings, the construction of an experimental set of wings containing a total of six cannon, and the initiation of a design study of a Typhoon variant with thinner wings of reduced area and lower profile drag. This latter study was later to arouse interest at the Air Ministry and eventually resulted in the Tempest. However by October 1940, enthusiasm had been revived and production of the Tornado and Typhoon reinstated production deliveries of both being scheduled for the following year.

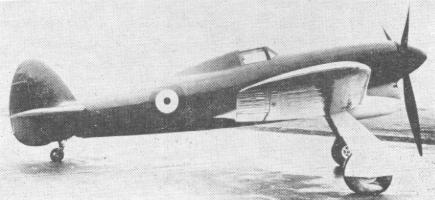

The first prototype Typhoon (P5212). The Tornado weighed 8,200 lbs. empty and 10,580 lbs. loaded. Its maximum speed was 425 mph at 23,000 feet. A.V. Roe had prepared a production line at Woodford and the first production Tornado (R7936) was delivered early in 1941. But this was fated to be the only production Tornado for difficulties with the Vulture resulted in the decision to remove this power plant from the aero-engine development program, this decision also canceling production of the Tornado. However in February 1941, Hawker received a contract to convert a Tornado to take a Bristol Centaurus radial engine. Among the modifications required were a new center fuselage and engine mounting. The new prototype (HG641) was assembled from Tornado production components and flown for the first time on October 23, 1941. The first Centaurus installation had an exhaust collector ring forward of the engine from which a single external exhaust stack pipe led back under the root of the port wing. This arrangement soon proved unsatisfactory, so the oil-cooler duct was enlarged and led forward to the nose, while twin exhaust pipes led back from the front collector ring through this fairing to eject under the belly of the fuselage. A level speed of 421 mph was attained with the Centaurus-Tornado, and this was slightly higher than that attainable by the Sabre-powered Typhoon, but the Typhoon airframe could not be adapted to take the radial engine. The second prototype Tornado (P5224) had in the meantime, been completed and the sole production Tornado (R7936) later played a useful role as a test-bed for de Havilland and Rotol contraprops. The first production Typhoon IA (R7082) with the 2,200 hp Sabre IIA engine was completed by Gloster and flown on May 26, 1941. Production of this version, with its twelve Browning guns was in limited quantity and those built were used principally for the development of operational techniques. But the cannon-armed Typhoon IB was following closely on the heels of the Mark IA, and the Air Ministry was pressing for its rapid service introduction to counter the new Focke-Wulf Fw 190. Nos. 56 and 609 Squadrons based at Duxford began to receive their Typhoons in September 1941, before the fighter was fully developed and these squadrons were forced to take on part of the onus of unearthing the new machine's numerous faults. The decision to use the Typhoon before it was adequately developed for operational use was ultimately justified by the results, but the price of its premature introduction was high. In the first nine months of its service life, far more Typhoons were lost through structural or engine troubles than were lost in combat. Between July and September 1942, it was estimated that at least one Typhoon failed to return from each sortie, owing to one or other of its defects. Trouble was experienced in power dives—a structural failure in the tail assembly sometimes resulted in this component parting company with the rest of the airframe. In fact, during the Dieppe operations in August 1942 when the first official mention of the Typhoon was made, fighters of this type bounced a formation of Fw 190s south of Le Treport diving out of the sun and damaging three of the German fighters, but two of the Typhoons did not pull out of their dive owing to structural failures in their tail assemblies.

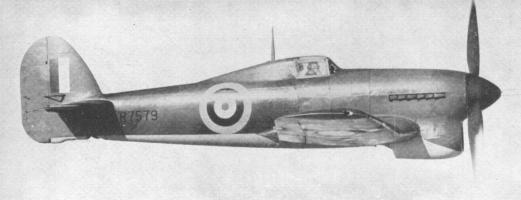

An early production Typhoon IA with a solid rear cockpit fairing. Despite this inauspicious start to its service career and the unenviable reputation that the Typhoon had gained, operations continued and the accident rate declined as the engine teething troubles were eradicated. However, the tail failures took longer to solve despite immediate strengthening and stiffening as soon as the trouble manifested itself. In November 1942 No. 609 Squadron, led by Wing Commander Roland Beamont, was moved to Manston in an attempt to combat the near-daily tip-and-run raids which were being made by Fw 190s and could rarely be intercepted by Spitfires. The Typhoon enjoyed almost immediate success. The first two Messerschmitt Me 210 fighter bombers to be destroyed over the British Isles fell to the guns of Typhoons and during the last comparatively ambitious daylight raid by the Luftwaffe on London, on January 20, 1943, five Fw 190s were destroyed by Typhoons. On November 17, 1942, Wing-Commander Beaumont had flown a Typhoon on its first night intrusion over Occupied France and subsequently the fighter was employed increasingly for offensive duties, strafing enemy airfields, ships and railway transport. The success of the Typhoon in the ground-attack role led to trials with two 250-lb. or two 500-lb. bombs which were carried on underwing racks. This load was later increased to two l,000-lb. bombs, but the Typhoon was not to find its true element until it was adapted to carry airborne rocket projectiles—four under each wing. By D-Day in June 1944, the RAF had twenty-six operational squadrons of Typhoon IBs. Without its underwing load the Typhoon IB weighed 11,300 lbs. and with two 500-lb. bombs and the necessary racks, 12,400 lbs. Maximum speed was 398 mph at 8,500 feet and 417 mph at 20,500 feet and an altitude of 20,000 feet could be attained in 7.6 minutes. Between the prototype and production stages, several design changes had been made. These included the re-design of the fin and rudder, the redisposition of the wheel fairings and the introduction of a clear-view fairing behind the cockpit. On the first few Typhoon IAs, the solid rear fairing was retained. Later a transparent fairing was fitted, but this was abandoned in favor of the first sliding " bubble " hood to be used by an operational fighter. The Typhoon IB by now affectionately known as the "Tiffy", distinguished itself particularly in the Battle of Normandy where it decimated a large concentration of armor ahead of Avranches, disposing of no fewer than 137 tanks and opening the way for the liberation of France and Belgium. For use in the tactical reconnaissance role, the Typhoon F.R.IB was developed early in 1945. In this version the two inboard cannon were removed and three F.24 cameras were carried in their place. One Typhoon was also converted as a prototype night fighter with A.I. equipment, special night-flying cockpit and other modifications. Production of the Typhoon which was entirely the responsibility of Gloster Aircraft, totaled 3,330 machines. Work had been going on in the Hawker design office since 1940 on the development of a new thin wing section. It had already been established that the NACA 22-series wing section employed by the Typhoon was entirely satisfactory at speeds in the vicinity of 400 mph, but encountered compressibility effects at higher speeds. In dives approaching 500 mph a very sudden and sharp increase in drag was experienced, accompanied by a change in the aerodynamic characteristics of the fighter which affected the pitching moment and rendered the machine nose heavy. No actual design work on the new wing was begun until September 1941 and the wing section eventually adopted for development had its point of maximum thickness at 37.5% of the chord. The thickness/cord ratio was 14.5% at the root and 10% at the tip, making the wing five inches thinner at the root than that of the Typhoon.

A late production Typhoon IB with "bubble" type canopy. This thin wing could not contain a comparable quantity of fuel to that housed by the Typhoon's wing so a large fuselage tank had to be adopted. This necessitated the introduction of an additional fuselage bay, increasing the overall length by twenty-one inches forward of the c.g. This added length found its inevitable compensation after initial prototype trials in a larger fin and tailplane. The wing area was also increased and an elliptical planform was adopted, presenting a chord sufficient to permit the four Hispano 20 mm cannon to be almost completely buried in the wing. All these modifications added up to a radically changed Typhoon, but it was as the Typhoon II that two prototypes were ordered in November 1941. However in the middle of the following year, the name Tempest was adopted. Alternative installations of the Sabre engine were designed for these prototypes; the first (HM595) had a Sabre II and a front radiator similar to that of the standard Typhoon, while the second (HM599) had a Sabre IV engine and wing leading-edge radiators. Piloted by Philip Lucas, the first prototype Tempest was flown on September 2, 1942, but prior to this in February 1942, a production order had been placed and the first production machine flew in June 1943 with Bill Humble at the controls. During flight trials the first Tempest prototype had exceeded 477 mph in level flight and the first production model was essentially similar to the first prototype with the chin-type radiator. This was designated Tempest V and the initial production batch, the Series I, had Mk. II cannon which projected slightly ahead of the wing leading edge, but the Series II had the short-barrelled Mk. V cannon which did not project and also featured a detachable rear fuselage, small-diameter wheels, and a rudder spring tab. Powered by a 2,420 hp Sabre IIB engine, the Tempest V attained a maximum speed of 435 mph at 17,000 feet. The 820-mile range of the Tempest V in clean condition was an appreciable improvement over that of the Typhoon and was due not only to the small additional quantity of fuel carried, but to the aerodynamic refinement of the later machine which permitted a higher cruising speed for the same power. The first squadrons to be equipped with Tempest Vs were Nos. 3 and 486 at Newchurch, Dungeness, the first of these receiving its equipment early in 1944. By May, five Tempest Vs had been lost due to engine failure and this was discovered to be due to an over speeding of the propellers, resulting in an uncontrollable increase in engine revolutions, the failure of the bearings and the collapse of the oil system. In June, modified propellers were fitted which solved the problem and two days after the invasion of the Continent on June 8, 1944, the Tempests met enemy aircraft in combat for the first time, destroying three Bf 109G fighters without loss to themselves. On June 13, the first V1 flying bombs were launched against England, and the Tempest, being the fastest low-medium altitude fighter in service with the RAF, became the mainstay of Britain's fighter defense against the pilotless missiles destroying 638 of these weapons by the beginning of September. The Tempest V was also employed on the Continent for train-busting and ground-attack duties.

A production Tempest V series I with the protruding Mk. II cannon. Meanwhile, the second prototype (HM599), designated Tempest I had proved sufficiently promising for production plans to be initiated. In the light of experience gained with the Centaurus-powered Tornado and the suitability of the Tempest fuselage for the radial engine, a Centaurus version of the Tempest was also initiated as the Mark II and production drawings were prepared in parallel with those of the Mark I. In the event, the Tempest I was later abandoned while the Mark II was allowed to proceed to the production stage, following the successful flight trials with the prototype, LA602 which commenced on June 28, 1943. The first production Tempest II flew fifteen months later, but the first unit, No. 54 Squadron, was not equipped with this fighter until November 1945, and was thus too late to participate in the war. The Tempest II was powered by the 2,500 hp Bristol Centaurus V or VI eighteen-cylinder, air-cooled, two-row radial, and attained a maximum speed of 440 mph at 15,900 feet and 406 mph at sea-level. Its range on internal fuel was 775 miles and initial climb rate was 4,520 ft./min. Schemes for the utilization of the Griffon IIB and the Griffon 61 engines accounted respectively for the Tempest III and Tempest IV designations, neither passing the project stage. Nor did an alternative armament proposal based on the use of 0.5-in. machine-guns. The final Tempest variant was the Mark VI, whic, appearing in 1945 was powered by the 2,700 hp Sabre VA engine and, except in having small intake ducts in the wing roots, was outwardly indistinguishable from the Tempest V. By and large, both the Typhoon and Tempest escaped the fate of so many aeroplanes of being used as test-beds for a variety of experiments. The Typhoon was designed in a naval fighter variant to meet the requirements of specification N.11/40, and one prototype was converted to this standard under the Hawker project designation P.1009. Another Typhoon modification, the P.1010, was to have had leading-edge radiators and a turbo blower, but work on this was not proceeded with. As part of their engine development program, Napier's designed an annular cowling for the Sabre to replace the familiar chin-type radiator bath. The first such installation was on a Typhoon IB (R8694), but most of the development was undertaken with a Tempest V (NV768) which flew with several different types of annular radiator and hollow spinner. Another experimental Tempest V (SN354) had a 40-mm. gun under each wing in a long fairing. As the Typhoon's immaturity faded it achieved widespread acclaim as a "rocketeer", being transformed from a fighter of dubious reliability into one of the Allies' most potent weapons. Likewise, its progressive development, the Tempest, gained for itself a place in the history of the air war for its part in reducing the depredations of the V1 flying bombs against England.

The final Tempest variant, the Mk VI, powered by a Napier Sabre VA. |

| Specifications: | |

|---|---|

| Tempest F.Mk.V Series II | |

| Dimensions: | |

| Wing span: | 41 ft 0 in (12.49 m) |

| Length: | 33 ft 8 in (10.24 m) |

| Height: | 16 ft 1 in (4.90 m) |

| Weights: | |

| Empty: | 9,250 lb (4,195 kg) |

| Maximum: | 13,500 lb (6,123 kg) |

| Performance: | |

| Maximum Speed: | 435 mph (700 km/h) @ 17,000 ft (5,181 m) |

| Service Ceiling: | 36,000 ft (10,972 m) |

| Range: |

820 miles (1,319 km) @ 210 mph (337 km/h) @ 5,000 ft (1,524 m) |

| Powerplant: | |

|

One Napier Sabre IIB 24-cylinder, liquid cooled, horizontal-H engine, providing 2,420 hp (1,804 kw) @ 3,850 r.p.m @ sea-level and, 2,045 hp (1,524 kw) @ 13,750 ft (4,191 m) | |

| Armament: | |

|

Four 20-mm Hispano Mk. V cannon with 150 rounds per gun and, eight 60-lb. rocket projectiles or two 1,000-lb. bombs. | |

© The Aviation History On-Line Museum.

All rights reserved.

Created March 22, 1997. Updated May 21, 2011.