|

Pratt & Whitney R-1340 Wasp |

|

| |

| |

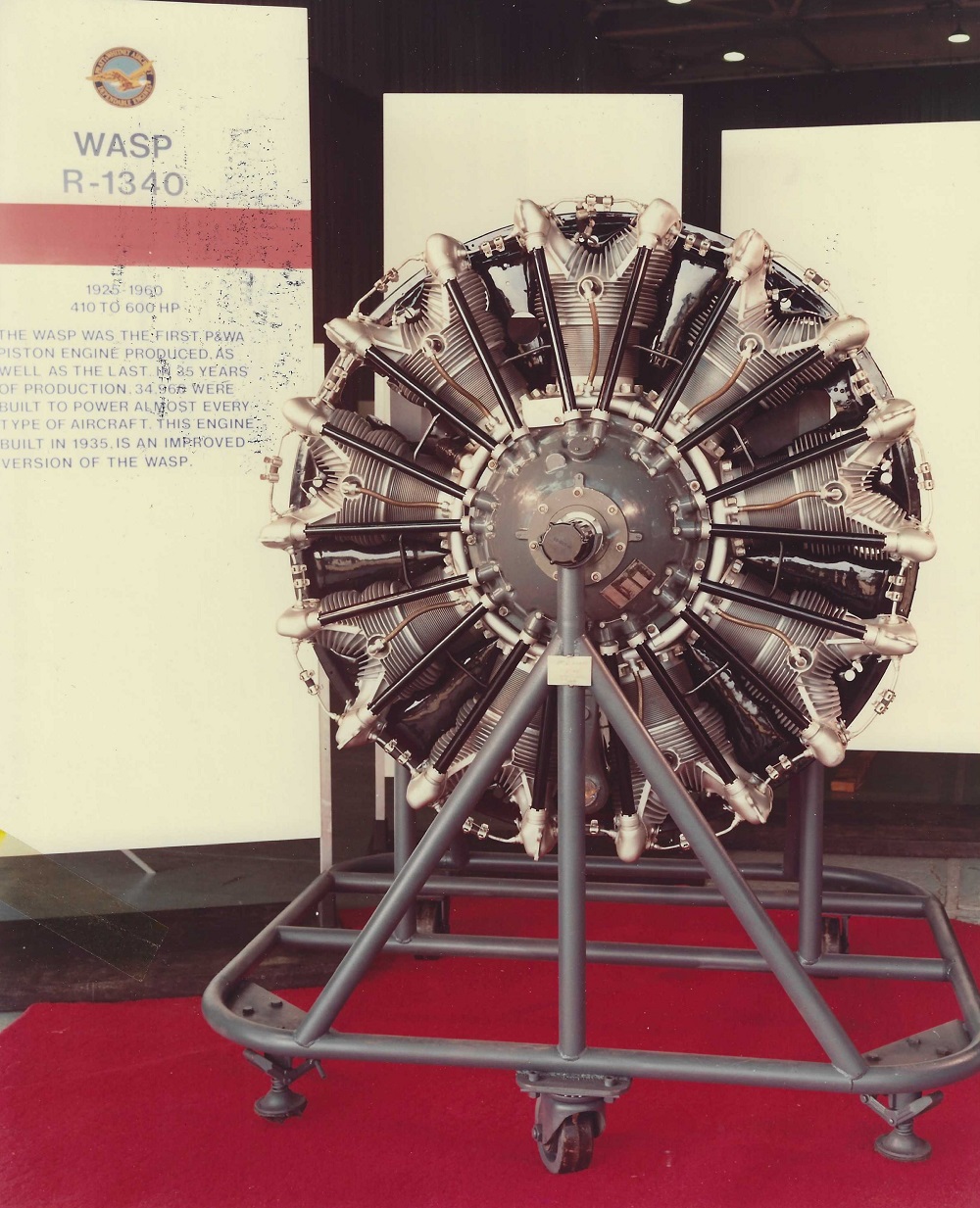

The original Pratt & Whitney Wasp engine, circa 1926. (Photo: NEAM Ramsay Research Library) | ||

|

The Pratt & Whitney R-1340 Wasp was a 9 cylinder, single-row, air-cooled radial engine with horsepower ranging from 410 hp to 600 hp, depending on the model and configuration. It was used in a range of aircraft that included the

North American AT-6,

Boeing P-26, and

Boeing 247.

Jimmy Doolittle used the Wasp to set records in his Gee Bee Racer and Emelia Earhart made history using the Wasp in

In the mid-1930s, Pratt & Whitney produced five basic engines: • The single-row Wasp Junior. • The single-row Wasp. • The single-row Hornet. • The double-row Twin Wasp. • The double-row Twin Wasp Junior. The Wasp was the first engine produced by Pratt & Whitney and it was completed December 24, 1925 at the new Pratt & Whitney Company, formed by Frederick Brant Rentschler. Pratt & Whitney had formerly been a longtime machine tool manufacturer. Rentschler had a background in internal combustion engines and more specifically aero engines since 1917. He graduated from Princeton and afterwards, he worked in his father’s machine company as a molder and machinist. When World War I started, he enlisted in the Army and was assigned to the aviation section for Aero Engine Production and Inspection. His main duties were involved with the inspection and production of the Hispano-Suiza engines then being built under license by Wright-Martin. In 1919, Rentschler played a leading role in the formation of Wright Aeronautical Corporation and became president of the company. Frustrated with Wright Aeronautical, he resigned in 1924 with an idea of producing his own engine. He was looking to build bigger and more powerful engines to be used in military and commercial applications. Rotary engines were now obsolete and liquid-cooled engines were still too heavy for the amount of horsepower they produced. The best American engines available at the time were the Curtis OX-5, the Liberty L-12 and the Curtiss D-12. What looked promising was the new Wright R-790 Whirlwind that Rentschler was involved with when he was president at Wright Aeronautical. This engine would eventually power Charles Lindberg’s famous Spirit of St Louis. England had also been working on developing radial engines since 1919 and the US Navy had been seeking a 200 hp air-cooled radial since 1921. Rentschler saw the future to be the lighter air-cooled radial engines in the 400-500 hp range. Building a new engine was a risky adventure following World War I. The market was flooded with surplus airplanes and engines. However, the US Navy was always in the market for a more powerful engine and Rentschler received further encouragement after calling on Rear Admiral William A. Moffett, of the Navy’s Bureau of Aeronautics. Rentschler told Moffett of his project and Moffett assured him if such an engine could be produced, the navy would be highly interested. Rentschler also had further discussions with Chance Vought who said that the military was in dire need of a 400 hp engine with a weight of less than 650 lbs. Chance Vought's UO-1 was standard with the US Navy's fleet. Rentschler received seed money from his Wall Street contacts in payments of $250,000 and $1,000,000. The first payment was for development of the prototypes and the second was for production. As would be the case for the Whittle turbojet engine fifteen years in the future, development of sophisticated aircraft engines demanded a lot of resources. Engine development is an expensive, lengthy process and aviation was no longer a one man show. In 1925, Rentschler had approached Pratt & Whitney, a machine tool manufacturer, to use some of their idle facilities. Their business had dwindled significantly after World War I and they also had surplus money to invest. Convinced that Rentschler’s idea was sound, they allocated idle manufacturing facilities and invested in his project. 1

Rentschler formed an engineering team to produce his new engine by convincing five of Wright Aeronautical’s top engineers in

design and production to come work with him. The five men who started with Rentschler were, George Mead, Andy Willgoos, Donald Brown, John Borrup and Charles Marks. Earl A. Ryder, an engineer from Aeromarine Plane and Motor company joined the team in July 1925. The design process began in the garage of Andy Willgoos located in Montclair, NJ. On August 3,1925 the Pratt and Whitney Company was reformed with half ownership going to the tool company and the other half to Fred Rentschler and George Mead and the entire team moved to Hartford, Connecticut.

The rotary blower and forged crankcase had been used before on the Armstrong-Siddeley Jaguar radial engine in 1919, but Pratt & Whitney arrived at their design independently.2

When the first engines were tested, they were rated at 410 hp.3 The Wasp proved so successful that the US Navy ordered 200 engines in October 1926.4 Before the sixth Wasp was even produced, Andy Willgoos was already working on a new and larger design, the Hornet. The Hornet was similar in many ways to the Wasp and many parts were interchangeable. By 1928, the military version of the Wasp was producing 450 hp; by 1933 power was up to 550 hp and eventually reached 600 hp.5

During testing, it was found that the machining of the engine was so precise that the engine had to be torn down to loosen up the piston rings, because they were too tight.6 Loosening the rings allowed some oil to bypass the pistons to improve lubrication of the cylinder walls. In order to save weight, the original Wasp engines were produced with Duralumin gears that passed during testing, but did not hold up in day-to-day operations. The aluminum gears were eventually replaced by steel components, but by this time, the engine had already proven itself. The Wright XF3W-1 Apache was used as a test bed for the Wasp until 1930 and made several records up to this date. On September 6, 1929, the XF3W piloted by Apollo Soucek set the world altitude record for seaplanes of 38,500 ft (11,700 m) and then on April 6, 1930, Soucek set the landplane altitude record of 43,166 ft (13,157 m). Almost 35,000 Wasps were produced from 1926 until the end of production in 1960.7 It was an instant success from the very start and many Wasp engines are still flying today. |

There were many improvements to the Wasp engine. Over 90 versions of the R-1340 engine are in operation today. | ||

| Specifications: | |

|---|---|

| Pratt & Whitney R-1340 Wasp | Date: | 1926 |

| Cylinders: | 9 |

| Configuration: | Single-row, Air-cooled radial |

| Horsepower: | 410 hp (305 kW) |

| RPM: | 2,250 |

| Bore and Stroke: | 5.75 in. (146 mm) x 5.75 in. (146 mm) |

| Displacement: | 1,344 cu. in. (22 liters) |

| Weight: | 640 lbs. (290 kg) |

Endnotes:

|

1. The Pratt & Whitney Aircraft Story. Pratt & Whitney: 1950. 11. |

Return To Engine Index.

© Larry Dwyer. The Aviation History On-Line Museum. All rights reserved.

Created September 26, 1996. Updated August 12, 2024.